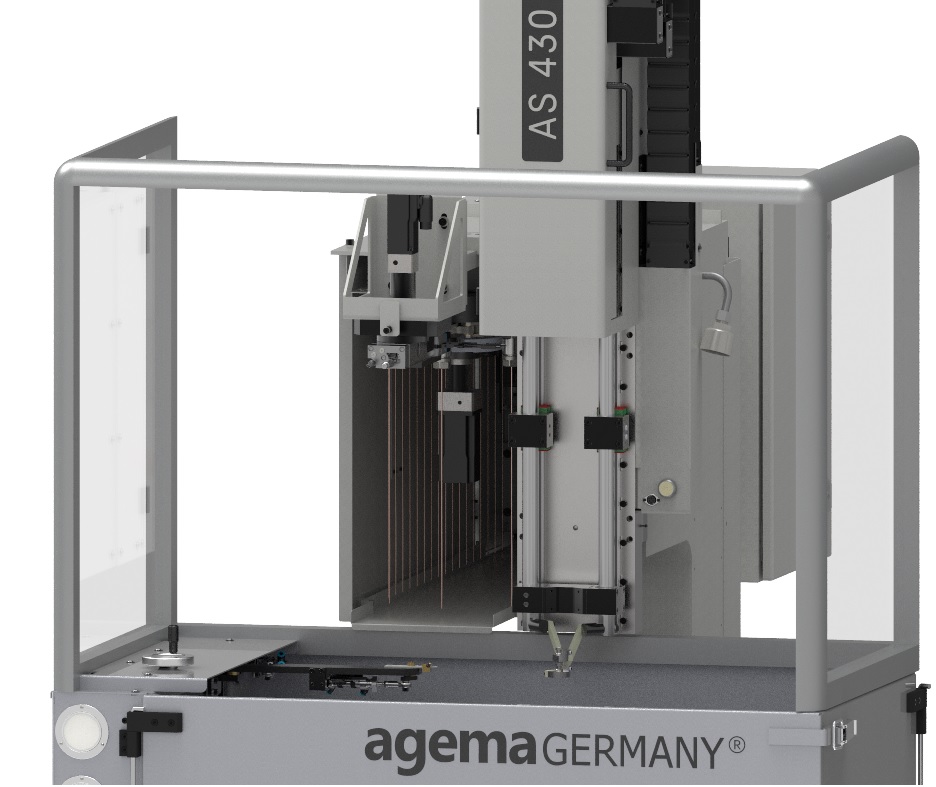

40-fold Tool Changer

12/18-fold Tool Changer

Second high-precision guide

Second guide, which increase process stability, accuracy and removal rate. Drillings with a larger aspect ratio can be eroded. More information.

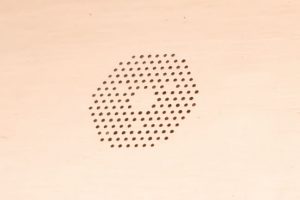

Sinker EDM, e.g. EDM Threading

EDM Threading / EDM Tapping can be made due to predefined Sinker EDM Technologies.

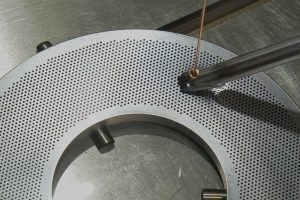

Small Hole Drilling

A small hole drilling module for micro drillings with d < 0,30 mm.

Contact us for a testpart free of cost!

Fifth or Further Axes

E.g. CNC-controlled dividers as fifth axis.

Up to eight axes possible.

Handbox

The handbox can be used additionally to operate the machine. It can be used to move the axes.

Remote Maintenance

Our service team can perform remotely diagnostics on your machine to help you as quickly as possible. Remote maintenance also leads to reduction in service costs for you.

OPC UA-Server

Output of all operating conditions, depending on the requirements.

Clamping systems & Electrode holders

Various clamping systems can be used on AGEMA EDM machines. These can be used for fast and precise changing of different electrode diameters or also for linking several machines.

Extraction and Filter Systems

With this system process-related vapors and gases can be removed directly from the working area – in accordance with the guidelines and regulations for air pollution control at workplaces.

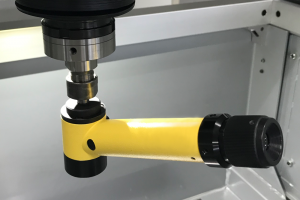

Centering Microscope

A centering microscope can be helpful in the case of increased precision requirements for regular control and adjustment of the center position when changing the electrode guide. It can also be used for the contactless recording of workpiece references for small and touch-sensitive workpieces.