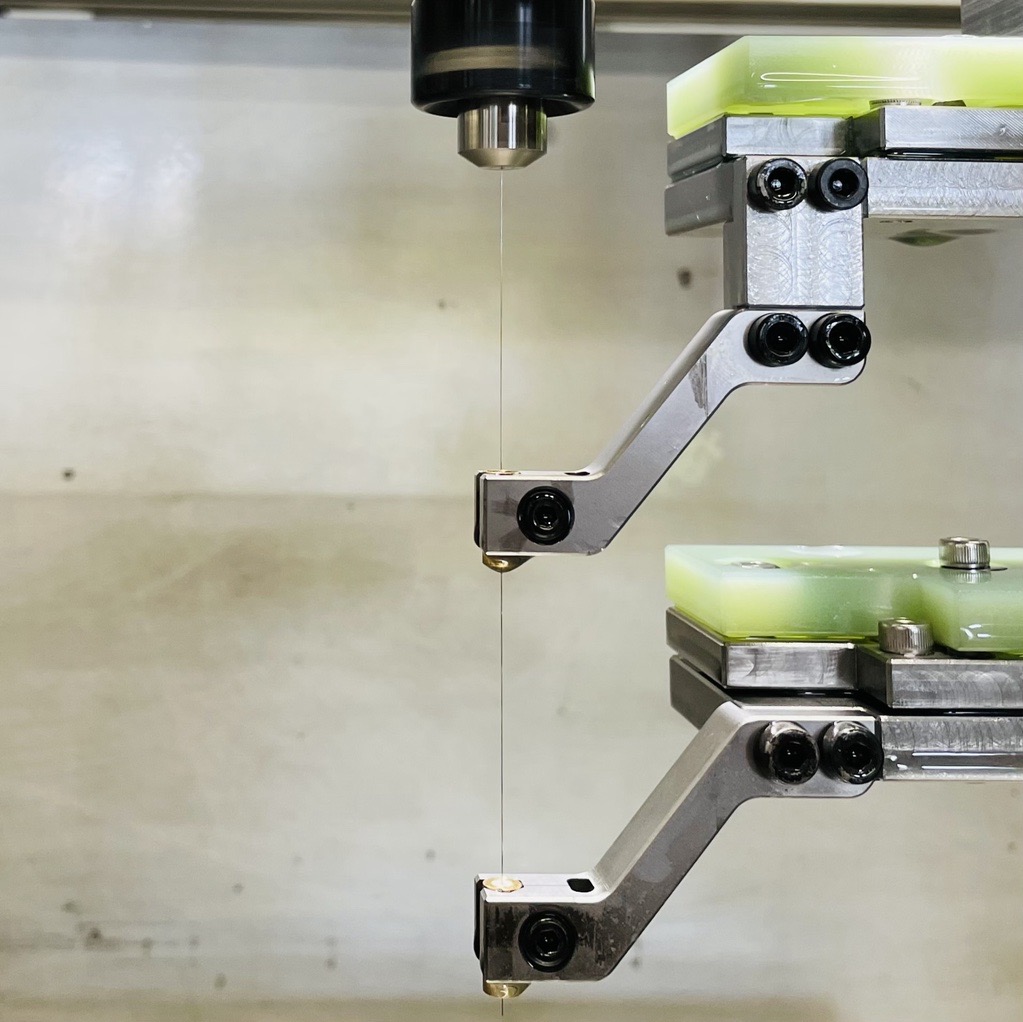

Precision EDM Startholedrilling machines Made in Germany

We have high demands when it comes to quality and precision of our Precision EDM Start Hole Drilling Machines. We therefore offer you a CNC Start Hole Drilling Machine „Made in Germany“: from first designs to completion.

high-precision start hole drilling & die sinking machines

We are leading manufacturer of innovative and high-precision EDM Start Hole Drilling Machines. AGEMA has its origins in Switzerland. Here the machines used to be manufactured under the name of AGEMA Swiss.

Today, AGEMA start hole EDM drilling machines are systematically developed further under the name AGEMA Germany by our in-house development & design department in line with customer requirements at our site near Pforzheim.

We are constantly developing our technology, particularly in the areas of small hole edm drilling/micro drilling, fast hole edm drilling, deep-hole drilling and carbide erosion.

When it comes to the automation of AGEMA start hole edm machines, we are also pleased to develop individual solutions together with our customers.

firstclass service

We genuinely care for our customers. Therefore we offer you a distinct and exquisite support throughout the entire operating time of your machines. We offer you an allround-service for your AGEMA machine. You can also find the right eroding accessories, such as electrodes, guides and collets, from us.

We are also pleased to help you find the right spare parts for your EDM machine. We offer you a comprehensive and fast spare parts supply for AGEMA Swiss and AGEMA Germany start hole edm machines. We are also happy to support you personally on site with repairs to your AGEMA machine. We also offer you the opportunity to have your machine serviced and checked at regular intervals.

Our team of experts is always available by phone or online for questions and advice. Give us a call or write to us via our service ticket system.

excellence & reliability

Our longlasting AGEMA EDM Startholedrilling machines can be used reliably for hole drilling EDM and EDM Threading for decades. Based on our understanding of quality, the machines are developed and assembled at our site in Straubenhardt.

The fast hole edm drilling machines are also suitable for very precise small hole EDM drillings < 0.30 mm. With an AGEMA, start hole drilling as well as small hole drillings can be machined quickly, with high quality and depth in carbide and steel.